Make Brass Industries

Make Brass Industries is a leading manufacturer of all copper alloy (copper, brass, bronze), aluminum, zinc alloy

Engineering Turned Components & Electrical assemblies. Our Product suits to all industrial sectors like faucets

fittings, sanitary components, Electrical & Electronics, Automobiles, Plastic Moulding Industry, and Construction &

Industrial Applications. Adding to this we make products according to the client's requirements.

Quality Assurance:

Our Competent Quality Assurance team is highly capable of providing an integrated quality assurance by following strict quality checking at every stage; right from incoming raw material to final dispatch, keeping up-to-date records of quality standards & following those qualities standards up to the advanced level. Quality types of equipment are timely calibrated ensuring proper controls. Vendors reports are verified periodically form external sources as per quality plans. In process stage inspection is controlled by following Statistical Measuring techniques like Variance analysis, SPC, X-Chart, R-Chart, trends, etc., 100% Visual checking is carried out to ensure 100% visual defect-free products.

Timely Delivery:

Implementation of Effective Inventory strategies like JIT (Just In Time) & Safety Stocks enable us to provide timely deliveries, reducing ordering cost & handling costs to Customers.

Skilled Engineering:

Our Skilled Engineers thrive to Improve the Yield of manufacturing resources thus increasing overall productivity.

The engineering department is responsible for Process establishment and continuous improvement for the

products and is responsible for related documentation and responsible for keeping the master samples. As such we

are a manufacturer of Custom products; Our Engineering Department does aid our customers in re-design the

products to make it more cost-effective with value engineering techniques.

Our Comprehensive Understanding & knowledge towards the application & critically for components in copper

alloy, makes us stand firm in the competitive market of business. Advance Techniques, latest machinery, our policy

of continuous upgrading our technology, process & system means us to get invited to more business, in fact, royal

business.

Why Us?

23 Years' Expertise in Turning Brass Parts

R.O.H.S Compliant Products

Impeccable Quality

Exclusive Manufacturing of the Customized Products

Product Designing Aid for Components' Cost Efficiency

On-Time Delivery

Effective Inventory Strategies Like JIT (Just In Time) & Safety Stocks

Free & Quick Quote

Simple & Effective Transparent Pricing Structure

Special Price for Long Run Contact Manufacturing on Mass Production

ERP Based Management Systems

Spare Capacity

Capacious Warehouse

Group Establishment:

1998

Location:

Jamnagar City (Gujarat) INDIA

Present Business Scope:

Manufacturing & Exports of Copper Alloy based Brass Engineering Turned Parts

Specialization:

Precision Turned & Machined Components Exclusively in Brass & Other related Copper Alloys

Key Operating Machines:

Automatic Bar Turning Trobe Type Lathe Machines Multi-Station Rotary Disc Transfer Indexing Machines for Secondary Operation, Wire Draw Machines, CNC Working.

Other Machinery:

Wire Draw Machines, Wire Rolling & Strengthening Machine, Hand Operate & Automatic Turning Machines, Hand Operate & Salt Threading Machines, Power Press, Drilling Machines, Hydraulic Power Press, Slotting Machines, Lathe Machine, Threading Machines, Grinder Machines, Hand Press, Role Thread Machines.

Measuring Instruments:

Micrometer, Vanier, Calliper, Vanier Height Gauge, Thread Plug Gauge, Ring Gauge, Pin Gauge, Dial Gauge Thickness Radius & Pitch Gauge, Chamber Gauge.

Brass Foundry:

We are having Two Foundries (It is a Factory that produces Metal Castings)

Work Space:

4300 Square Feet

Working Hours:

8-30 am to 6-00 pm (1 Hour Lunch Break & 15 Minutes Tea Break)

Explore Now

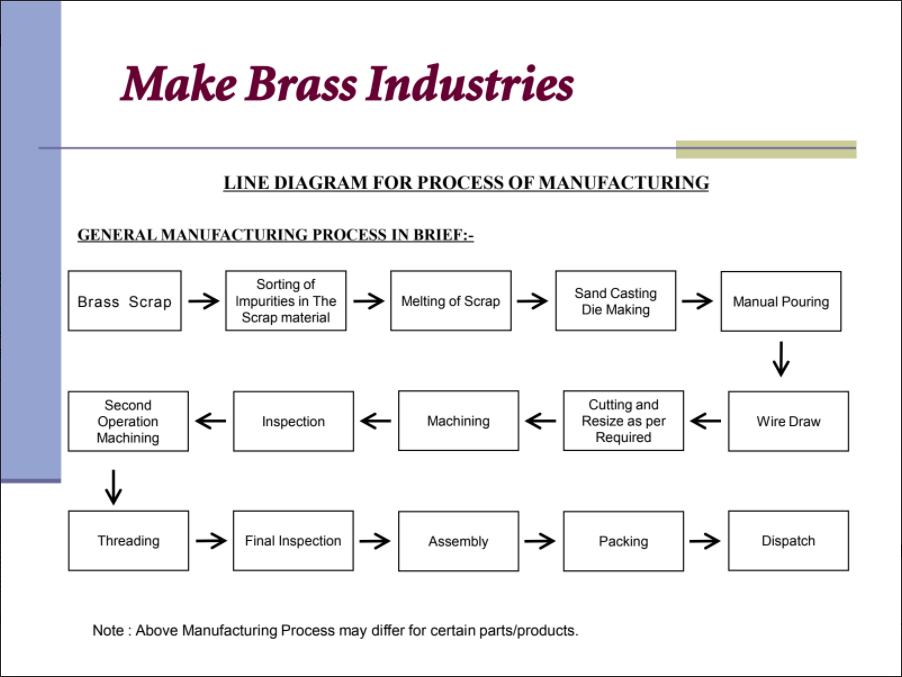

Whole Process Scenario